Dust Control

Calcium Chloride in Dust Control Applications

Still the Most Effective Dust Control Agent

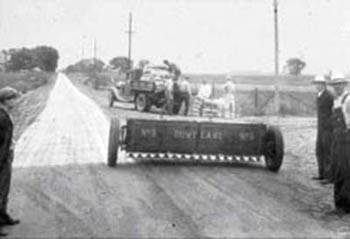

That was then…

This is now…

Why is dust control important?

- Road officials must contend with higher maintenance costs because a dusty road is a deteriorating road. Once the fine material is lost, the load-bearing aggregate will soon follow. Loss of fines and aggregate results in ruts, potholes and washboards that require costly spot repairs and frequent bladings to keep the road in acceptable condition.

- Road users face the serious safety issue of reduced visibility and also the prospect of loose gravel causing cracked windshields, chipped paint and/or broken headlights.

- Local residents must contend with large quantities of dust drifting into their living environment, reducing their quality of life and increasing their chances of developing respiratory health problems.

Why use calcium chloride for dust control?

- Calcium chloride attracts moisture from the air, keeping the road damp even under hot, dry conditions. The moisture film provides a cohesive force that binds aggregate particles together, resulting in a hard and compact surface.

- A beneficial residual effect accumulates with consistent application year after year. As calcium chloride becomes established deeper in the roadbase, stability improves and frost damage is prevented.

- Calcium chloride manufactured by Dow has been used for dust control applications since the early 1920’s. No other dust control product or manufacturer comes close to this level of proven performance.

How can road managers with tight budgets justify expenditures for dust control with calcium chloride?

Several years ago, road managers in South Africa asked this question and subsequently launched a series of field trials to collect the necessary data to develop an answer.1 Here are some of the results from their work.

- Blading frequency of roads treated with calcium chloride decreased by about 50% and the expected interval between re-graveling increased from 7 to 14 years.

- A cost/benefit analysis of various maintenance alternatives for a road with 342 ADT indicated that annual application of calcium chloride with a 90 day blading cycle maximized the economic benefits for road managers and road users.

- The greatest economic benefits were realized when aggregate replacement costs and ADT are both high.

This work shows that a dust control program with calcium chloride can be considered an investment that provides a good rate of return, in addition to improving the quality of life for road users and neighbors alike.

Suggestions for Effectively Using Calcium Chloride in Dust Control

Table 1. Dust Control Application Rates (US Unites)

| Product | Unpaved Roads | Truck Terminals & Parking Lots | Mine Haul & Logging Roads |

| LIQUIDOW™ 35% | 0.30 gal/yd2 2117 gal/lane-mi |

0.33 gal/yd2 2352 gal/lane-mi |

0.39 gal/yd2 2744 gal/lane-mi |

| LIQUIDOW 38% | 0.27 gal/yd2 1901 gal/lane-mi |

0.30 gal/yd2 2112 gal/lane-mi |

0.35 gal/yd2 2464 gal/lane-mi |

| LIQUIDOW 42% | 0.24 gal/yd2 1664 gal/lane-mi |

0.26 gal/yd2 1849 gal/lane-mi |

0.31 gal/yd2 2157 gal/lane-mi |

| DOWFLAKE™ 77-80% | 1.50 lb/yd2 5.28 ton/lane-mi |

1.70 lb/yd2 5.98 ton/lane-mi |

2.00 lb/yd2 7.04 ton/lane-mi |

| DOWFLAKE™ Xtra 83-87% | 1.38 lb/yd2 4.84 ton/lane-mi |

1.56 lb/yd2 5.49 ton/lane-mi |

1.83 lb/yd2 6.45 ton/lane-mi |

| ANHYDROUS 94-97% | 1.23 lb/yd2 4.33 ton/lane-mi |

1.39 lb/yd2 4.90 ton/lane-mi |

1.64 lb/yd2 5.77 ton/lane-mi |

*lane-mi equals 4 yards wide by 1760 yards long

| Product | Unpaved Roads | Truck Terminals & Parking Lots | Mine Haul & Logging Roads |

| LIQUIDOW 35% | 1.36 liter/m2 5027 liter/lane-km |

1.51 liter/m2 5604 liter/lane-km |

1.76 liter/m2 6511 liter/lane-km |

| LIQUIDOW 38% | 1.22 liter/m2 4514 liter/lane-km |

1.36 liter/m2 5032 liter/lane-km |

1.58 liter/m2 5846 liter/lane-km |

| LIQUIDOW 42% | 1.07 liter/m2 3951 liter/lane-km |

1.19 liter/m2 4404 liter/lane-km |

1.38 liter/m2 5116 liter/lane-km |

| DOWFLAKE 77-80% | 0.81 kg/m2 3.01 tonne/lane-km |

0.92 kg/m2 3.41 tonne/lane-km |

1.09 kg/m2 4.01 tonne/lane-km |

| DOWFLAKE Xtra 83-87% | 0.75 kg/m2 2.76 tonne/lane-km |

0.85 kg/m2 3.13 tonne/lane-km |

0.99 kg/m2 3.68 tonne/lane-km |

| ANHYDROUS 94-97% | 0.67 kg/m2 2.47 tonne/lane-km |

0.76 kg/m2 2.80 tonne/lane-km |

0.89 kg/m2 3.29 tonne/lane-km |

*lane-km equals 3.7 meters wide by 1000 meters long

| Characteristic | Preferred | Acceptable |

| Maximum Size | 3/4 inch | 1 inch |

| Grading Description | Well graded – not uniform or skip graded | |

| Percent Pass #4 | 55 to 70 | 50 to 75 |

| Percent Pass #200 (Nonplastic) | 14 to 17 | 12 to 17 |

| Percent Pass #200 (Plastic) | 12 to 15 | 8 to 15 |

| Plasticity Index | 2 to 9 | Nonplastic |

| Los Angeles Abrasion | Less than 30 | Less than 40 |

| Percent Fracture, one face | Greater than 85% | Greater than 75% |

Additional Information

To ensure the safe and effective use of calcium chloride, please thoroughly review the product’s Material Safety Data Sheet prior to use. To obtain an MSDS, contact the Peters Chemical Company at 1-973-427-8844 or visit the Calcium Chloride web site at www.peterschemical.com.

1 “The Incorporation of Dust Pallaitives as a Maintenance Option in Unsealed Road Management Systems.” D. Jones, E. Sadzik, and I. Wolmarans; Paper from 20th ARRB Conference, 19-21 March 2001

- Blade in the spring, while road moisture content and humidity are relatively high. Water road surface prior to blading unless rain has fallen within the last two days. Remove ruts, washboards, potholes and mix in loose aggregate.

- Good drainage is essential to good performance. Shape roads to a 4% or greater crown. Ditches, shoulders and culverts should be reshaped and cleaned as needed.

- Recommended application rates are provided in Tables 1 and 2. When applying solid products, it is usually preferable to water the surface prior to spreading the product. If the road is kept open to traffic while solid product remains on the surface, signs should be posted directing motorists to take appropriate precautions.

- Applications should not be started during heavy rainfall or if rain is threatening.

- For best performance, aggregate should meet the criteria shown in Table 3.

- During unusually long periods of hot, dry weather, water the road surface during early morning hours as needed to reconstitute the treatment. Re-apply in late summer or early fall as needed.

Frequently Asked Questions

Will an unpaved road treated with calcium chloride corrode my vehicle?

Noticeable vehicle corrosion is not likely to result from driving on an unpaved surface treated with calcium chloride. The calcium chloride tends to stay bound to the soil in the road, so there is little chance for significant contact with exposed metal on a vehicle.

Are dust control treatments with calcium chloride safe for the environment?

Calcium chloride dust control applications reduce sediment load on waterways and save thousands of tons of aggregate that otherwise would be mined from noisy and unsightly gravel quarries. Airborne particulate matter is reduced, improving regional air quality. Ground and surface waters are not likely to be impacted. While over-exposure to chloride has the potential to injure trees, this rarely occurs in dust control applications that follow current standard practices.

Notice: No freedom from any patent owned by Seller or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance with applicable laws and other governmental enactments. Seller assumes no obligation or liability for the information in this document. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.